Description

Graffitiguard™ Appearance Retention Coating is an anti-graffiti coating that ensures appearance retention against the strongest elements.

The Graffitiguard™ Appearance Retention Coating is a permanent protective graffiti removal layer that prevents paint particles from penetrating the porous structure of mineral surfaces where they could become permanently embedded. This protective layer is dirt repellent and oil repellent: the sealant repels water ingress, dirt, moss, lichen and fungus from adhering to absorbent substrates such as stone, concrete, terracotta and brick and has a functional lifespan of over ten years.*

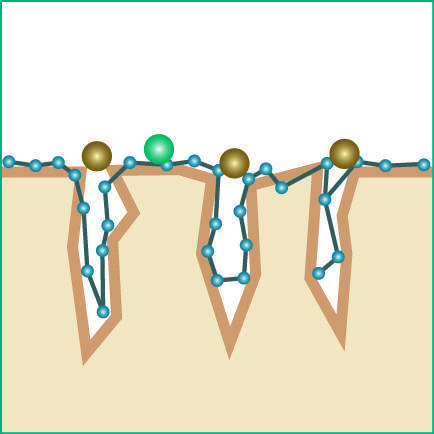

The Graffitiguard™ Appearance Retention Coating creates a nanoscale, breathable 3D coating on the substrate that permanently repels dirt and water from any porous mineral structure. The molecular fusion of the active ingredient to the surface also guarantees permanent protection against weathering, mechanical and chemical abrasion. It is therefore classified as “non-sacrificial” graffiti protection, which will withstand multiple graffiti removals with the appropriate agent. The Graffitiguard™ Appearance Retention Coating has wear resistance equivalent to the substrate that it’s applied to. Re-application of the coating adjacent to existing applications is easily achieved. All coated substrates exhibit 3-fold freeze/thaw resistance (EN1338).

This non-stick nano-care product is designed for many surface applications on public buildings and circulation areas such as underpasses, bridges, schools and external cladding, as well as surfaces that are prone to high levels of dirt and contamination (particularly chewing gum) and surfaces that require appearance retention.

For a lower concentration product please look at Flexiguard™ Stone & Paving Sealant

Graffitiguard Appearance Retention Coating is part of the ‘building protection’ range of water-repellent spray SiO2 products that preserve, protect and restore multiple building surfaces. These weather resistance coatings are often used in building repair and building preservation processes. Continuous product development using hybrid technology and innovative techniques has created the most advanced range of dirt repellent and oil repellent solutions for new and existing buildings.

*Please note that the initially strong pearling effect can diminish after a few years due to the deposit of fine dust particles. However, this in no way impairs the protection.