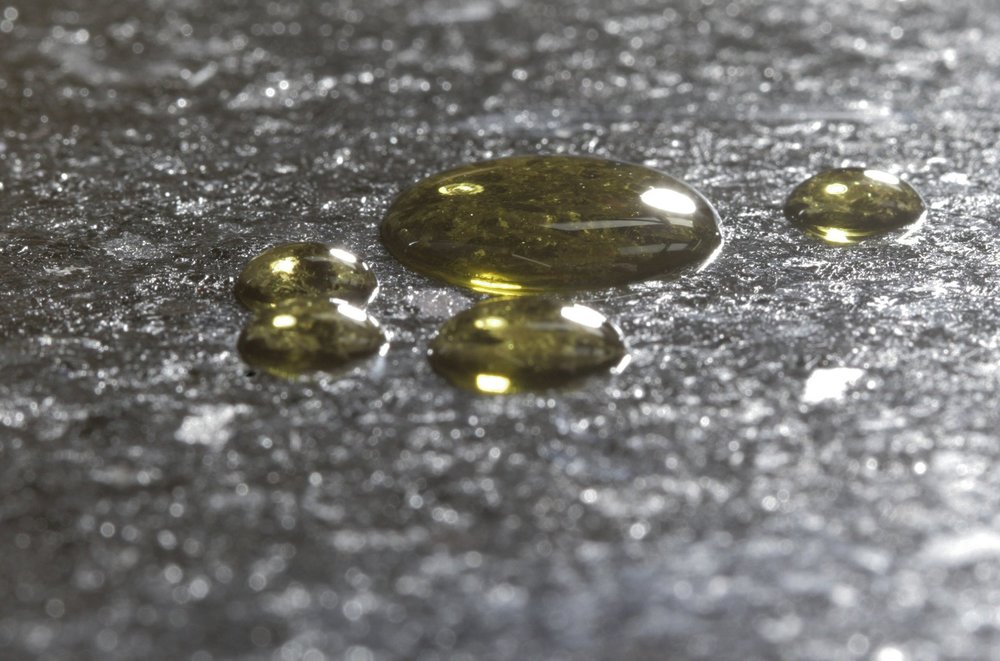

Nano ceramic coatings are the solution to maintaining the value of surfaces, they have a range of key features that set them apart from other surface coatings: –

- Non-stick: water and dirt repellence, offers long-term protection and facilitates cleaning.

- Graffiti and stain protection: barrier properties of ultra-dense ceramic and quartz structures protect from dirt and contamination ingress.

- Scratch protection: surfaces are more resistant to wear and tear.

- Corrosion prevention: ultra-density halts rust at source.

- UV- protection: anti-ageing preserves valuable surfaces.

- High temperature resistance: No change in characteristics under intensive heat (up to 1000 degrees)

- The perfect finish: Colour enhancement and gloss bring outstanding aesthetics to surfaces.

- Easy-to-apply: The perfect finish is achieved without the need for special training.

Nano ceramic coatings for automotive applications

Within the automotive industry Dura nano ceramics can be used to:

- Protect car bodywork and alloys from scratches, dirt and ageing

- Universal protection from corrosion

- Improves durability of decorative plastics and headlights

- Prevention of brake dust permanently bonding to wheel rims

Nano ceramic coatings for aviation applications

Dura nano ceramics offer long-term protection in the aviation sector through:

- Protecting airplane fuselages from dirt and ageing for up to ten years.

- Facilitating de-icing

- Improving the durability of decorative and strongly stressed plastics and non-absorbent synthetic materials.

- Protecting surfaces from damaged caused by vandalism

Nano ceramic coatings for marine applications

The marine environment is particularly harsh due to the corrosive nature of salt water. Nano ceramics have the ability to:

- Protect hulls from ageing, corrosion and provide anti-fouling protection for up to ten years.

- Protection against corrosion for metals used on decks

- Delay wear and tear of decorative elements on deck

- Facilitate easy cleaning of saltwater residues

Nano ceramic coatings for architecture and construction

Nano ceramics can be used on external and internal surfaces to maintain aesthetics:

- Protecting kitchen worktops made of quartz, granite, and marble from stains

- Preventing visible fingerprints on structured surfaces such as stainless steel kitchen exhaust hoods, elevators and handrails.

- Long-term protection for aluminium, synthetic or stainless-steel facades from UV radiation and weathering by acid rain for up to ten years.

Nano ceramic coatings for industry and manufacturing

Industrial plant and equipment are significant capital investments and as such companies can look to protect their investments through the use of Dura nano ceramic coatings to protect the against surface corrosion, calcification, wear and tear and dirt:

- Easy clean performance in food production i.e. production lines, tanks and mixers, making wash downs quicker and using less water.

- Non-stick coating for pipelines and reactors used in the chemical industry, machines and utility vehicles.

- Easy displacement of biofilms