Description

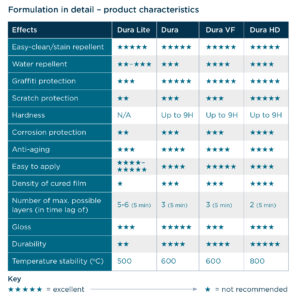

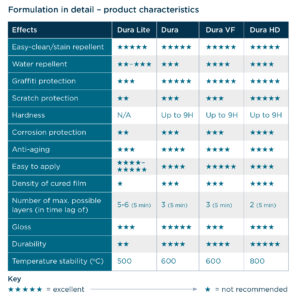

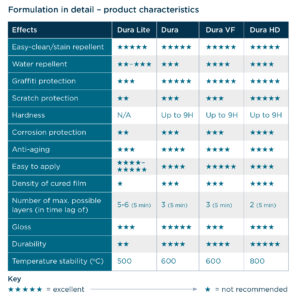

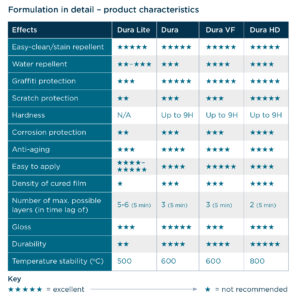

Dura VF Nano-ceramic, combines inorganic and organic nano-ceramic’s to give substrates water and dirt repellence with high level durability against mechanical ware. The inorganic groups provide Dura with the ability to adhere to synthetic and metallic substrates with a pencil hardness of 9H, while the organic groups generate the superior non-stick benefits. Dura is a range of three different strengths;

- Dura Lite – Lowest concentration of active ingredient

- Dura VF – Standard concentration of active ingredient

- Dura HD – Highest concentration of active ingredient.

They all share the same core features, but offer different levels of functionality, depending on application need.

Key core features of the range

- Non stick: Water and dirt repellence offers long-term protection and facilitates cleaning.

- Graffiti and stain protection: Barrier properties of ultra-dense ceramic and quartz structures protect from dirt and contamination ingress.

- Scratch protection: Surfaces are more resistant to wear and tear

- Corrosion prevention: Ultra-density halts rust at source

- UV-protection: Anti-ageing preserves valuable surfaces

- High temperature resistance: No change in characteristics under intensive heat (up to 1000 degrees)

- The perfect finish: Colour enhancement and gloss bring outstanding aesthetics to surfaces.

- Easy-to-apply: Perfect finish is achieved without the need for special training.

Dura is used with-in the following sectors:-

- Manufacturing

- Transport

- Architecture and building construction

- Marine

For more information relating to sector use Click here

Hazards

Danger

H261 In contact with water releases flammable gases.

H302 Harmful if swallowed.

H314 Causes severe skin burns and eye damage.

H332 Harmful if inhaled.

EUH208 Contains 3-aminopropyltriethoxysilane. May produce an allergic reaction.

P210 Keep away from heat, hot surfaces, sparks, open flames and other ignition sources. No smoking.

P232 Protect from moisture.

P260 Do not breathe mist/vapours.

P273 Avoid release to the environment.

P280 Wear protective gloves/protective clothing/eye protection/face protection.

P301 + P310 IF SWALLOWED: Immediately call a POISON CENTER/doctor.

P303 + P361 + P353 IF ON SKIN (or hair): Take off immediately all contaminated clothing. Rinse skin with water [or shower].

P304 + P340 IF INHALED: Remove person to fresh air and keep comfortable for breathing.

P305 + P351 + P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy

to do. Continue rinsing.

P310 Immediately call a POISON CENTER/doctor.

P402 + P404 Store in a dry place. Store in a closed container.

P501 Dispose of contents/container in accordance with national regulation.

Application Instructions

Dura Range (Dura Lite, Dura, Dura HD and Dura VF)

1) Drops of the liquid are applied either on a slightly absorbent cloth or directly to the substrate.

2) Spread across the surface with a light polishing motion.

3) After approx. 1-3 minutes visible streaks are removed with gentle polishing motions.

4) This high-performance coating is waterproof after 24 hours and fully cured after 7 days.

Use a clean lint free cloth for application and wear gloves