Nano-ceramic products developed with high-level expertise in nanoscale molecular bonding across a breadth of hard substrates. We market a range of high quality ceramic coatings which fulfill multiple purposes within commercial manufacturing, trade and domestic settings, including: vehicle protection, mould release, scratch resistance, non stick, anti-corrosion and easy clean performance.

The Dura Nano Ceramic Range provides non-absorbent paint work, glass, alloy finishes and other non-absorbent surfaces with outstanding 9H pencil hardness “nano-ceramic” protection, providing long-term easy-clean performance, scratch resistance and protection against oxidisation.

Dura forms an ultra-thin barrier with a strong chemical bond to the OH surface that is permanent, durable and resistant against mechanical (abrasive) and chemical (cleaning) action, UV damage as well as general environmental weathering .

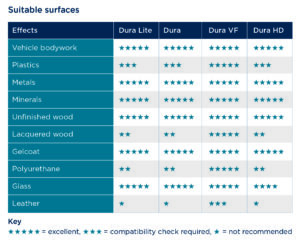

Dura’s performance makes it ideal for preserving and extending the life of many surfaces in the following sectors:-

- Architecture and building construction – Building facades, interior fixtures and fittings such as stainless steel sinks, cookers and hoods where scratch resistance is paramount to maintaining the long life aesthetics of the surface.

- Marine – Protects hulls from ageing corrosion, while providing anti-fouling protection, facilitates easy cleaning of saltwater residues.

- Manufacturing – Machinery in manufacturing processes, especially those exposed to high temperatures ; Dura can withstand temperatures of up to 1000oc .

- Automotive Transport – Prevents ageing of bodywork and protects against corrosion; facilitates de-icing and protects surfaces from vandalism, suitable for use on :-

- Trains

- Trams

- Lorries

- Motorcycles

- Caravans

- Motor homes

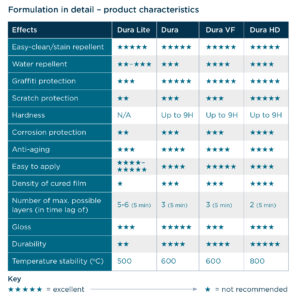

Dura is available in three strengths:-

- Dura Lite – lowest concentration of active ingredient

- Dura VF – standard concentration of active ingredient

- Dura HD – highest concentration of active ingredient

Dura VF Nano Ceramic

Dura is also available in the ultra-dense version Dura HD and Dura Lite version. The product is solvent-based and has an ammonia-based aroma. It is a hazardous material according to ADR and IATA. This complex technology cannot be diluted.

Please observe the relevant safety data sheet when using Dura Nano Ceramic.