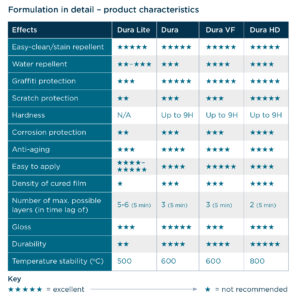

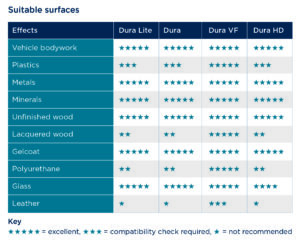

The Dura nano ceramic range provides non-absorbent surfaces (painted, stainless, plastic and natural stone) with reliable nanotechnology protection against a range of contaminants such as graffiti, acids and oxidisation.

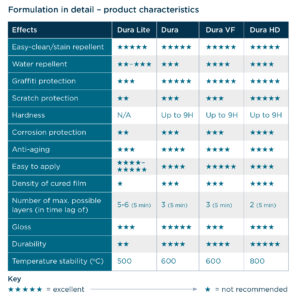

Dura forms an ultra-thin barrier with a strong chemical bond that is permanent and durable. Once applied to the surface, the nano coating resists damage caused by mechanical (abrasive) and chemical (cleaning) action, as well as general weathering.

The Dura range is a nano-ceramic coating that is particularly suited to clear view windows, commercial stainless-steel kitchens, domestic kitchens (including quartz worktops and ceramic hobs) and children’s outdoor play equipment.

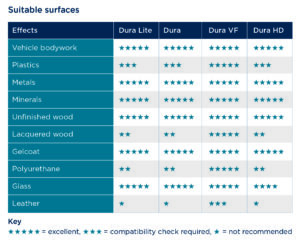

Dura is available in three different strengths as follows:-

- Dura Lite

- Dura VF

- Dura HD

Dura’s performance makes it ideal for preserving and extending the life of many surfaces in the following sectors:-

Architecture and building construction – Building facades, interior fixtures and fittings such as stainless steel sinks, cookers and hoods where scratch resistance is paramount to maintaining the long life aesthetics of the surface.

Marine – Protects hulls from ageing corrosion, while providing anti-fouling protection, facilitates easy cleaning of saltwater residues.

Manufacturing – Machinery in manufacturing processes, especially those exposed to high temperatures; Dura can withstand temperatures of up to 1000oC

Transport – Prevents ageing of bodywork and protects against corrosion; facilitates de-icing and protects surfaces from vandalism.